Manufacturing Process

Through our revolutionary building methods, Whisper Creek Log Homes provides primary residences and recreational cabins with a difference. Our homes have the appearance of a traditional “full log” product but without the inherent shortfalls such as shifting, cracking, checking and shrinking which is a cause of drafts and heat loss. Besides the lengthy construction time, a full log home is very expensive as well. We provide an affordable log home that is quick to build and provides long lasting, trouble-free stately beauty for years of enjoyment! Imagine sitting back and relaxing in your Whisper Creek Log Home – the ultimate in log home living!

One of the most enjoyable parts of building your new home will be to watch how quickly this process will go and how much time and money can be saved because of our unique process. This is what a first time new contractor recently had to say upon building one of our homes for a client. “I would like to start by letting you know how well built your house is. I made sure that my sub-floor was right on with your plans. With a lot of kit houses, the walls can be up to 1 inch short or long. Your walls were right on. I was pleasantly surprised. Everything with the package went together nicely.

Steve Green, Pindale, Wyoming

Click on the steps to your left to reveal Whisper Creek Log Homes' unique manufacturing process.

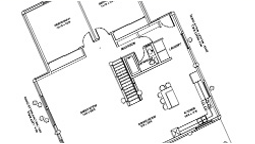

STEP 01 - The dealer helps the customer pick the model that best suits their needs.

STEP 02 - The order goes to the plant and the 2X6's for the walls are cut to dimension.

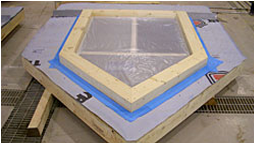

STEP 03 - The pieces are assembled on a template table, air nailed and para-lam beams are added over window and door openings.

STEP 04 - 7/16 inch wall sheathing is applied to shear wall standards and a quality house wrap is applied to protect the home against moisture.

STEP 05 - Each wall is custom built using 8 and 10 inch hand-crafted half logs which are fastened to the wall at the top and bottom at 16 inch intervals, fixed directly into 2X6's.

STEP 06 - Maintenance free, low-e, double-glazed vinyl windows are installed.

STEP 07 - The structure of the wall is now complete and is moved to the staining area where your choice of stain is applied to exacting specifications. Once dried, the finishing touch of your choice of chinking is added. This step, more than any other, creates a unique and rugged elegance to your home that us unmatched.

STEP 08 - At the other end of the plant, the porch components - 12 inch log posts and hand railing - are stained to match the walls of the structure.

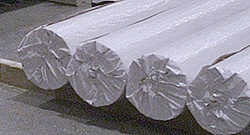

STEP 09 - Interior railing, stairs, 16 inch center post, 12 inch purlins, loft logs, end posts and brackets are all individually wrapped to protect them during delivery.

STEP 10 - Everything is loaded onto the trailers for transporation to the customer's site.

Authorized Whisper Creek Dealer

Authorized Whisper Creek Dealer